Bottom Bracket Selection Guide

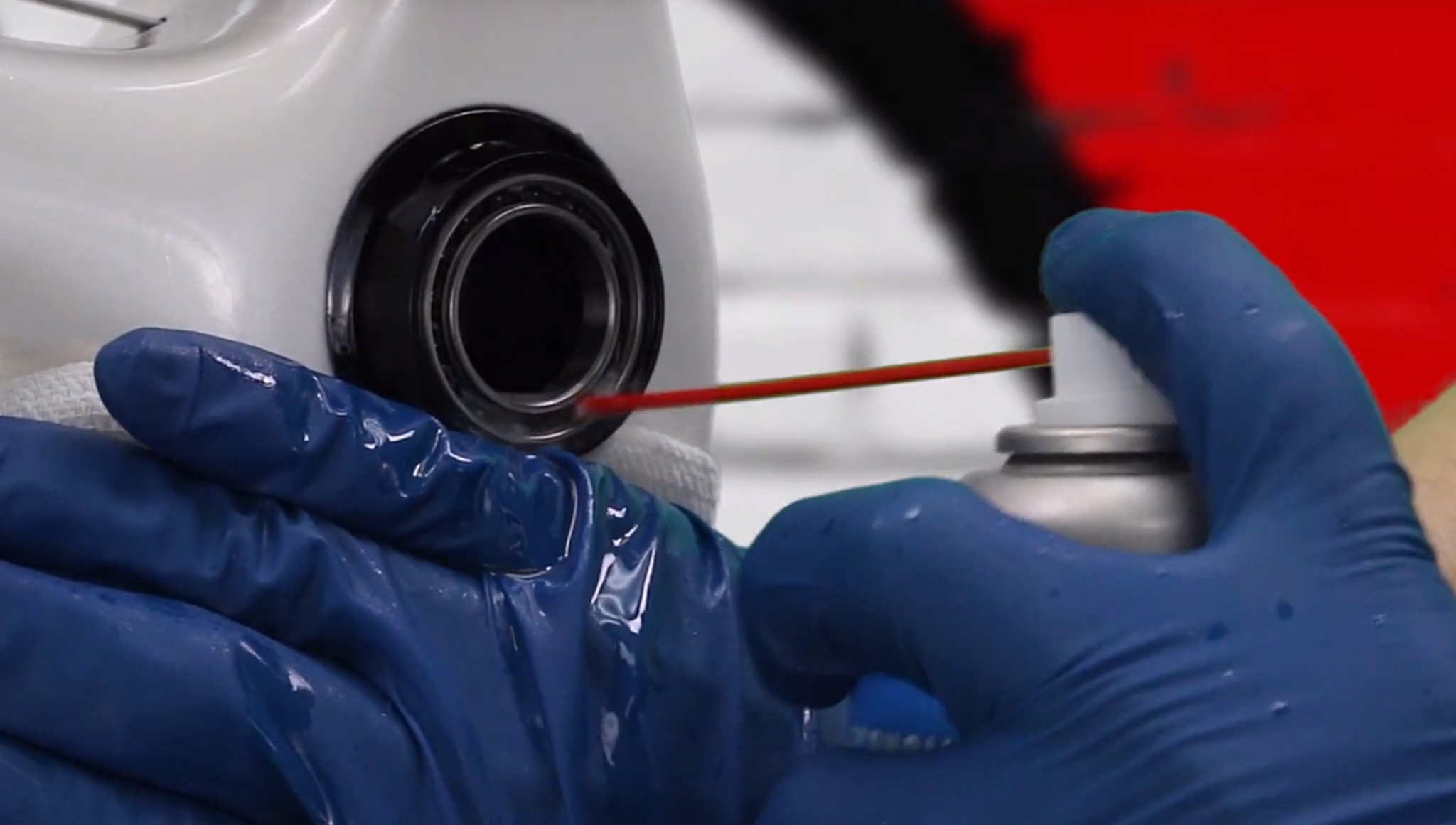

Once you’ve removed the crank and all the hardware to get down the bearings themselves, use a clean, new razor to carefully remove the outermost seals, by coming down into the edge like this, and just prying out very carefully. You’re not digging in with the blade now, of course, not a bit; You’re just using it to pry the seal out very carefully. Use WD-40 or Boeing Boeshield T-9 to flush the bearings out. And then we’re going to follow up with some White Lighting Clean Streak, to just get all the residue off, because this is going to be quite oily when I’m all done with it. You notice this sounds kinda like a little skateboard wheel, right there. That’s nothing to be alarmed about. That’s totally normal. That’s what happens when all the grease is removed. And once again we want to flush this out. Don’t squirt it in your eyes…flush this out, right here, get it nice and clean. We’re going to blow this out with compressed air. If you have it, or else you can let it air dry, especially if you set it out in the sun and it will dry in a very short amount of time. For Ceramitech bearings, insist on Kluber IsoFlex NB52, which works perfectly in steel bearings as well. You can buy a syringe, ready, pre-loaded with Kluber NB52 from the BBInfinite store. Fill each bearing to about 60-70%, and what you’re going to do is just work around the edge of the bearing, all the way around. Alright, work the grease into the bearings manually. Now this easy when you’re using the right product for the application. Never use a sticky or a tacky grease for bearing this small, especially bearings with extremely low mass, like these Ceramitechs, because the balls will slide through the grease rather than roll, like a ball bearing should. When a bearing feels draggy and laggy this is what’s generally going on if you just got done re-greasing it. So just kind of spin it until it loosens up. And reinstall the seal.

A clean bike is a fast bike, and this goes for bearings as well. We hope now you know how to clean your bike bearings. Maintaining you BBInfinite bottom bracket is fast and easy because it ought to be. Service your bearings every 2,000miles for road and most gravel bike applications. Service every 100hrs for mountain bikes and X-bikes in normal conditions. If you ride in the rain extensively you should perform maintenance more often no matter what type of bike you are using. Water is the eternal arch enemy of bearings. WHETHER YOU'RE FIXING A BOTTOM BRACKET CREAK OR YOU'RE LOOKING FOR PERFORMANCE ENHANCEMENT, BBINFINITE HAS EXACTLY WHAT YOU NEED. Product Selection Section Which type of bottom bracket module do I need?? Email us at info@bbinfinite.com and let know the bicycle frame type (e.g. road), frame manufacturer, frame model and model year, and crank type (manufacturer and model), and with this information we'll reply with a link directly to the product you need. Attach a few pictures showing the crank and bottom bracket area clearly, and one of the entire bicycle to aid us in our quest to get you on the right track. Creaking Bottom Bracket Section My bottom bracket is creaking and I've tried everything to fix it. How does a BBInfinite Bottom Bracket module fix a creaking problem? We fit creaking bottom brackets with proper engineering and precision machining. Watch this brief BBInfinite primer PressFit Perfection to get the lowdown on how we do it while all others fail. I heard that PressFit bikes just creak. Is that true? No, that is completely false information. PressFit bottom brackets offer the potential for the highest level performance possible, thanks to BBInfinite. There is no reason for your PressFit bike to creak, crunch, crack, or make any noises at all. Unless the frame is cracked the bike will be quiet. Can a creaking and popping bottom bracket damage my frame? Yes, it can. A creaking bottom bracket means there's movement between the bottom bracket and the frame. The more a bicycle bottom bracket creaks the more it is moving. This movement over time can wallow out the frame bottom bracket shell openings, enlarging them and elongating them, making them more susceptible to creaking and making it impossible to fit new bottom brackets. Don't freak out, it takes a long time. We've seen only a handful of bikes go in the junk heap due to bottom bracket shell ovalization. Install a BBInfinite module to save your frame, and your sanity. General Bottom Bracket Information Section How much do the modules weigh? Each module model has its weight published under the product description. Go to the BBInfinite bottom bracket page for the type of bottom bracket you desire and you'll find a series of tabs in the product description area. The "info" tab is open already. The last tab "specifications" is where you'll find the product weight along with its external dimensions. Do all BBInfinite Modules have bushings in the middle? No. Only modules designed for a 30mm spindle require a bushing due to variances in 30mm crank set design and "set up" from one manufacturer to another. These inconsistencies are mostly in the area of preload adjustment methods that put too much side load on the bearings. These over-preloading situations require the use of a bushing between the inner races of each bearing to ensure proper performance. Shimano DirectFit and Campagnolo DirectFit models do not need a bushing. GXP modules have a short bushing that reduces the bearing diameter on one side, but it is not a full length version found on BBInfinite 30mm crank spindle models. Can I use adaptors with a BBInfinite Module? We'd rather you didn't. Technically, it is possible, but such action departs from the basic principles of BBInfinite engineering methodology. Adaptors cause creaks and bearing alignment problems and are unnecessary when you can select the proper BBInfinite Module for your frame and crank set for a creak-free, high performance riding experience. How long do the bearings last? It varies. Road applications typically last 8,000-12,000 miles for steel bearings and 8,000-12,000 miles for Ceramitech bearings. MTB applications are entirely dependent upon conditions, especially water exposure. Example: A Category 1 MTB racer can usually go an entire season, racing a full schedule, on a single set of bearings of either type. Ceramitechs are better in wet conditions due to a high degree of corrosion resistance. Will a BBInfinite Module work with my power crank/power meter? Absolutely. We designed them specifically to be compatible with even the somewhat troublesome-to-fit older model SRM cranks. BBInfinite Modules are compatible with all power cranks/power meters.

Comments will be approved before showing up.